Introduction

What Will Your ID Card Look Like?

Starting with a vision for your ID Card and understanding your intended card design will make choosing the right printer much easier. When working with an identification company, we suggest sharing your ideas for the initial design of your card and providing a list of requirements for the finished product or a general description of how you want the card to look. This will allow a professional to suggest the right printer for the job.

Not sure where to start? This guide is aimed at providing an overview of the major considerations when choosing the right ID card printing solution. J. O’Brien has a team of experts that are happy to assist you!

Request a free consultationPrinter Brand

Compatible Software May Help you Decide Which Brand is the “Best Fit” for Your Needs

Just like most products we buy, there are multiple manufactures of ID card printers. Brand may be unimportant when printing from a program that works with any ID card printer, however it is very important to determine what software program you will be printing from, as it may only be compatible with certain brands of printers. In many industries there are already ID card printing software programs standards in place, so be sure to check for an existing system before you purchase an ID card printer.

Examples of ID Card Printer Brands include:

- Fargo- Fargo Buying Guide

- Datacard

- Zebra

- Magicard

- Nisca

- Evolis

Printer Model / Series

Think Volume, Quantity, Capabilities, and Media Type

In addition to there being many different printer brands, there are also different models of ID Card printers within each brand. Determining the correct model comes down to considering several factors such as volume, print quality, necessary capabilities, and the type of media on which you intend to print. Your goal should be to produce your desired ID card in the most efficient manner, both now and in the future.

Consider your ideal

ID Card Printer for both

NOW and in the FUTURE.

Print Volume

Two Criteria to Consider When Determining the Best ID Card Printer Model for You

1. DURABILITY:

It is important to select a printer that is designed for your specific needs. Determine roughly how many cards you will need to print each year and choose a printer model that is designed to produce that volume.

The expected volume in which you plan to print will dictate which printer model will be best for you.

For example, you wouldn’t want a printer that is designed for light volume (less than 100 cards a year) when you need to print thousands of ID cards each year. Doing so could stress the internal components of the machine, which will cause abnormal down time and/or service charges. The opposite is also true, you would not want to purchase a high-volume printer when you have a light-use demand.

2. OPERATIONAL EFFICIENCY:

Volume also plays into operational efficiency. Choosing the correct printer suited for your production demand is key when it comes to printer supplies and how frequently you will need to replace printer ink. High volume printers are designed to accept higher capacity ribbons, which lowers your cost per print (think bulk discount) and the time spent switching out ribbons.

Print Quality

Two Quality Factors to Consider When Choosing Your Ideal ID Card Printer

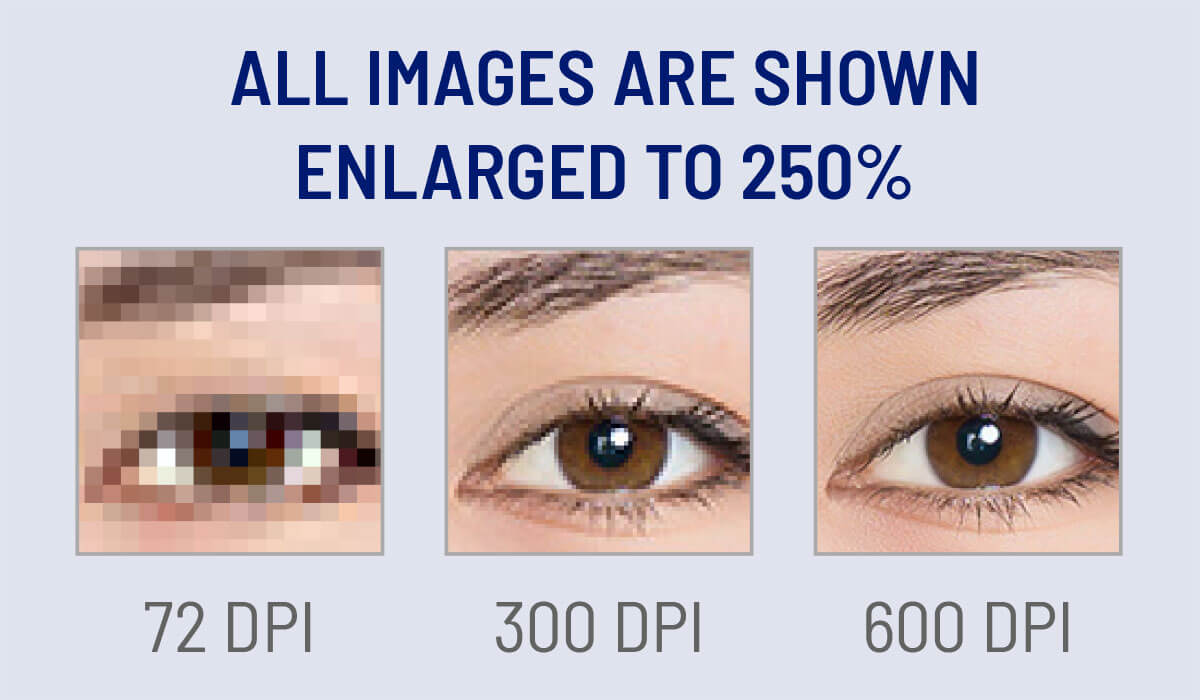

1. DPI:

DPI or “dots per inch” is the standard terminology associated with how detailed a printhead can produce images on a card. DPI capabilities in card printers are akin to the resolution on a television or phone screen. The higher the DPI or resolution, the more vivid and detailed the picture will be. Currently, standard printheads in the ID card printing industry are capable of printing 300dpi and 600dpi.

2. Print Method:

There are two technologies when it comes to printing identification cards.

Single or Dual-Sided Printing

Which Printer Option is Right for You?

Single-sided printers print on one side of a card, while dual-sided or “duplex” printers can print on both sides of a card in a single pass. Single-sided ID card printers are perfect for printing simple ID cards with limited information such as employee photo, name, and company logo, etc. They are also a smart choice if you only print a small volume of cards each year, generally under 500 cards. While single-sided printers can be used to print on both sides of a card, this is not recommended as it can cause printhead damage from dust and debris getting inside of the printer and having to run a card through the printer twice can be very time consuming. Dual-sided ID card printers print information on the front and back of a card at the same time allowing for more information to be shown. This is ideal for organizations, such as in healthcare, that need room to show more detailed information or have requirements where specific information must be visible no matter which side of the card is showing.

Printer Encoding Capabilities

Add to the Function and Security of Your ID Cards with Encoding Options

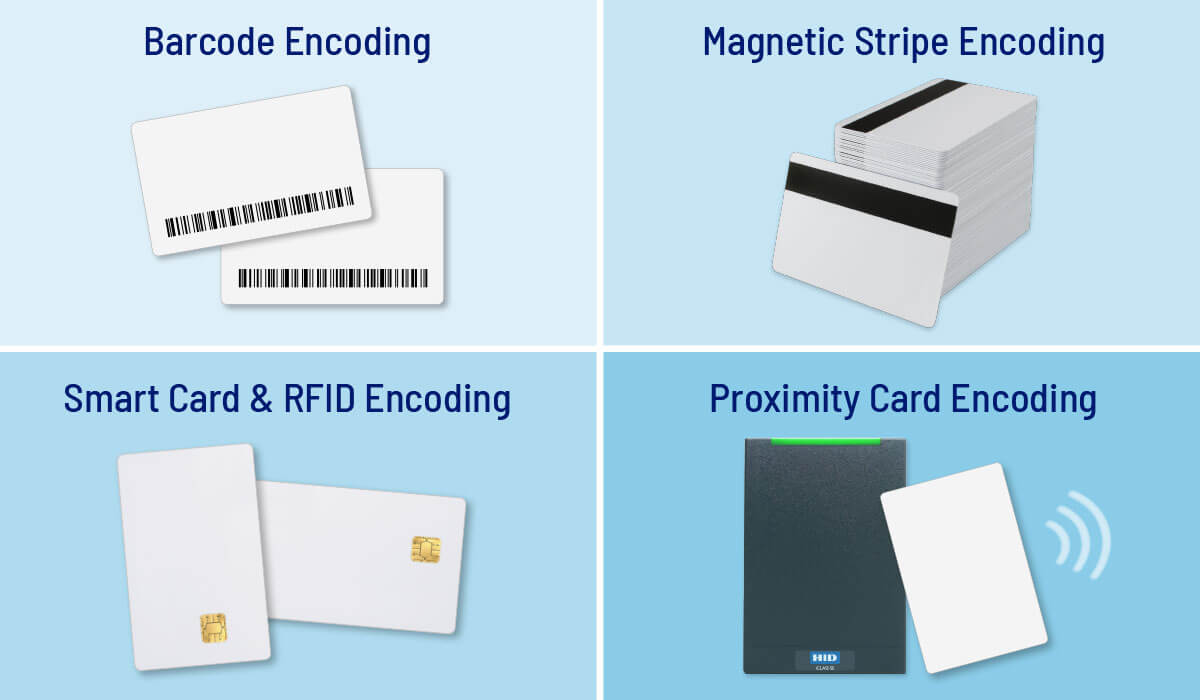

ID cards with barcodes or magnetic stripes, smart cards, and proximity cards are all types of encoded cards.

Encode your card to hold different types and amounts of data depending on your needs.

Encoding options allow you to read, write, or program a proximity or smart card. Advanced third party applications from brands such as Lenel, HID® and Datacard® require your printer to be able to encode unique information onto the cardholder’s internal or embedded smart chip. Make sure the printer, software and cards you choose can accomplish the type of encoding you need since not all software can encode every type of card.

ID Card Lamination For Added Durability

Want Your ID Card to Last Longer?

To protect the surface of your ID cards, consider purchasing an ID card printer with a lamination module inside. Just like the ID card printing portion of the machine, a laminator can be either single- or dual-sided capable. Lamination is particularly good for cards that will be swiped through a reader or used in active environments/outdoors.

Why Add Lamination to an ID Card?

- Increases the life of a card

- Adds durability to cards that will be swiped through a card reader

- Strengthens cards for use in active environments

- Keeps your card looking professional for longer

ID Card Visual Security

Apply these Features to Reinforce the Security of Your ID Card

1. Holographic Overlaminate

In addition to adding durability to your card, you can utilize a laminator module to apply a custom, high-security holographic overlay to your card. Adding a custom hologram requires an initial investment (setup fee + minimum order quantity), but it provides a crucial added layer of security against card forging. This feature is critical in high-security environments. If you like the look and benefits of hologram but don’t want to pay the extra costs for a custom design, most printer brands offer generic “off the shelf” holographic laminates that provide a unique look without the large MOQ (minimum order quantities). The lower cost of a generic holographic laminate does however have a trade-off; a thief with the right machine can still forge your card, but doing so will be more difficult than without a holographic overlay.

2. Watermark

Adding a layer of custom security to your card does not have to break the bank. An inexpensive yet slightly less secure method of adding to the uniqueness of your ID card is to purchase an ID card printer that can add a watermark by customizing the overlay that is used to seal in the image of your print. Depending on the brand of printer, the cost to add a custom watermark to your card varies, but is inexpensive compared to designing a holographic overlaminate.

3. Tactile Impressor

A tactile impressor module is a feature only offered through select printer brands. A tactile impressor can be installed into a printer to stamp each card with a raised generic or custom image. This is achieved using a dye that is installed and utilized to physically stamp each card that is produced. Adding a tactile impressor in addition or as an alternative to a custom laminate provides enhanced visual security. The raised nature of the impression is similar to the raised numbers on a credit card and makes it easy for your staff to validate an ID as legitimate.